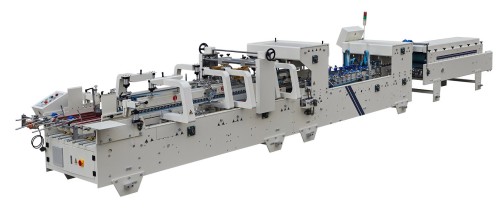

Auto Pre-Fold & Lock Bottom Folding Gluing Machine

- Model

- GDHH

Review

Description

1. The Feeder with 5-6 pcs of belts, converter speed, one-touch pneumatic knife, to ensure stable and smooth feeding motion.

2. The Pre-Folder with 2-board structure, extra long module to make carton folding perfectly and precisely.

3. Glue pot units for Crash Bottom Lock could be easily assembled and disassembled for different box type.

4. Extra long folding module to ensure high speed and reliable folding quality.

5. PLC touchscreen, Counting unit, with Kick marking device.

|

Model

|

GDHH900

|

Paper Material | Cardboard250-800g E-flute/F-flute E |

Max. Liner speed | Max. 280 meter/minute |

|

Feeding way |

Automatically and continuously feeding |

|

Way of folding |

Fold 1 and fold 3 are 180° Fold 2 and fold 4 is 90°and 180° Bottom folded and glued |

|

Glue Material |

Water-base cold glue |

Electric power | 7.5KW 380V 3P |

Weight | 2600KG |

Over dimension | 12500 x1400 x 1350mm |

|

Material

|

Cardboard |

E/F Corrugated

|

|

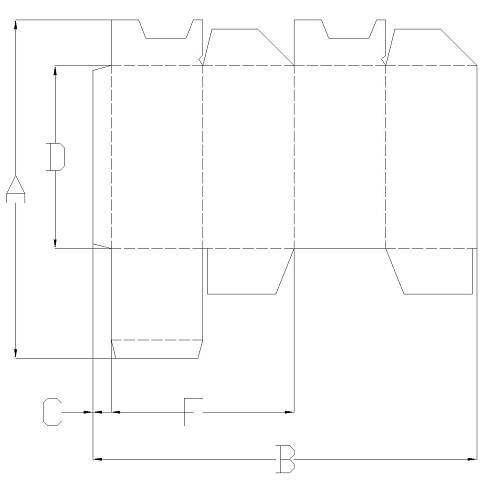

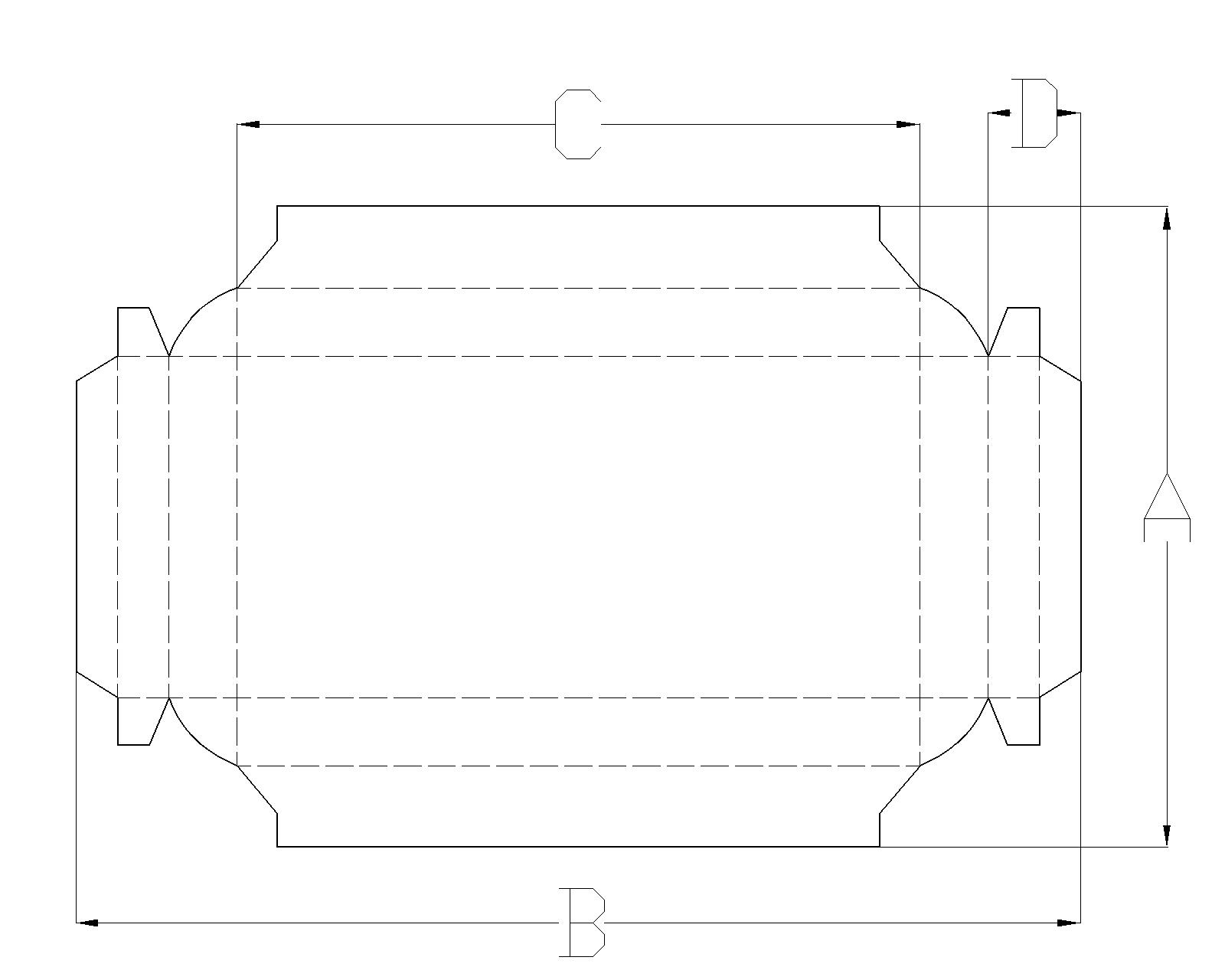

A

|

150-600mm |

150-600mm |

|

B

|

200-850mm |

200-850mm |

|

C

|

Min:10mm |

Min:10mm |

|

D

|

Min:70mm |

Min:70mm |

|

F

|

Min:80mm |

Min:80mm |

|

Material

|

Cardboard |

E/f Corrugated

|

|

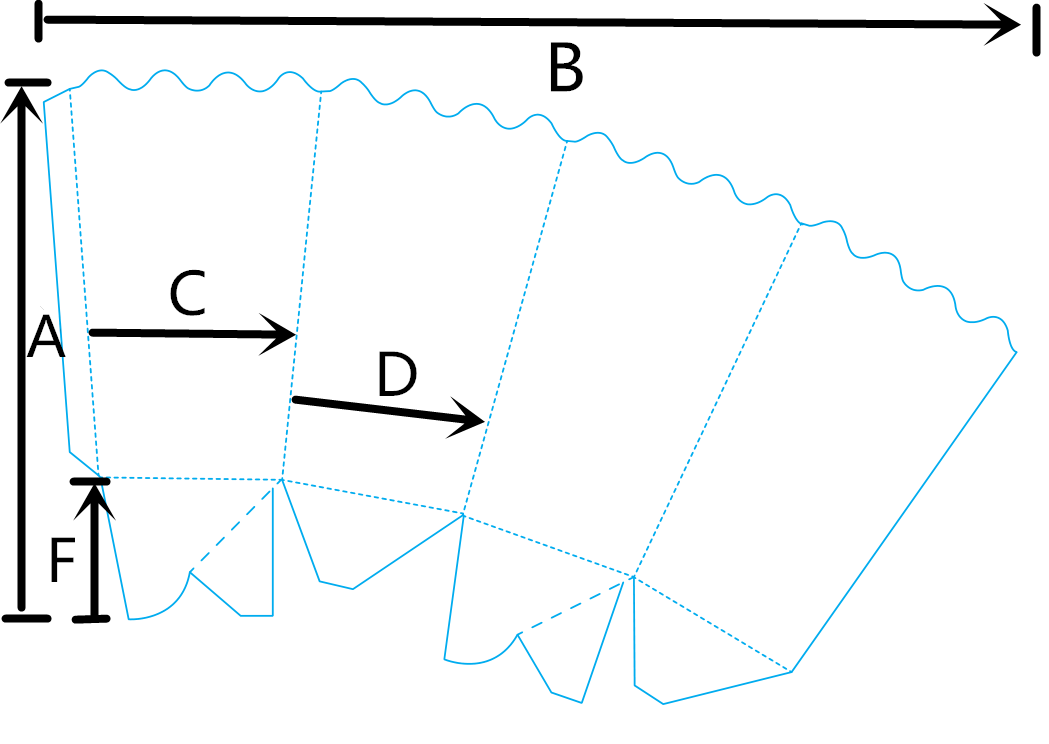

A

|

150-700mm |

120-700mm |

|

B

|

120-850mm |

180-850mm |

|

C

|

Min:10mm |

Min:10mm |

|

D

|

Min:70mm |

Min:80mm |

|

F

|

Min:80mm |

Min:80mm |

|

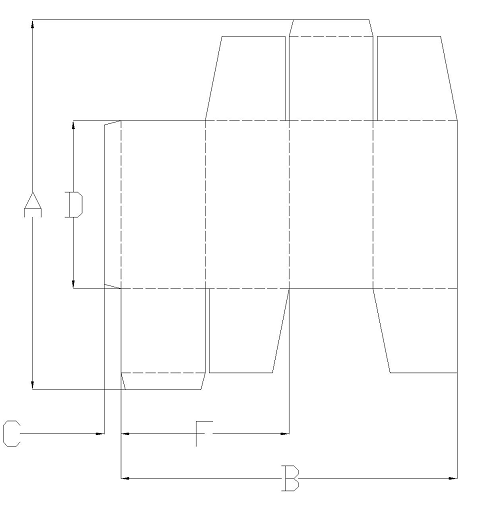

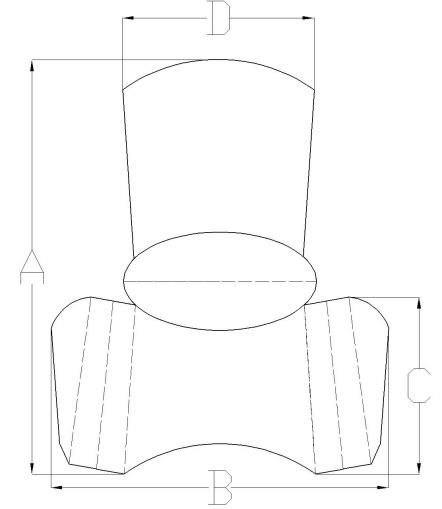

A

|

100-550mm |

|

B

|

100-800mm |

|

C

|

70-600mm |

|

D

|

10-200mm |

|

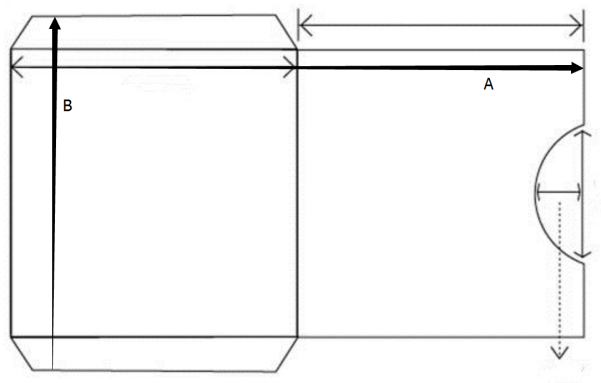

A

|

150-600mm |

|

B

|

180-850mm |

|

C (min)

|

40mm |

|

D (min)

|

35mm

|

|

F (min)

|

20mm

|

Note: Cold glue gun spraying system is optional | |

|

A

|

240-350mm |

|

B

|

190-250mm |

|

C

|

100-130mm |

|

D

|

85-110mm |

Note: Cold glue gun spraying system is optional | |

|

A

|

500-850mm |

|

B

|

100-700mm |

Note: CD box device is optional | |

5-6pcs Adjustable feeding belts to ensure easy adjustment, stable and smoothly feeding.

Continuously Variable Speeder to ensure feeding internal and stable transmission.

One-touch Pneumatic knife, easy for the adjustment of feeding belts.

Double-board structure with a set of pre-folding knife. Pre-fold angle is 180°and 90°, especially suitable for small but high cartons, more satisfactory while rapid prototyping.

Packed with special track device.

Lengthened folding to avoid the unevenness while the rapid forming of cartons and make it come to perfection.

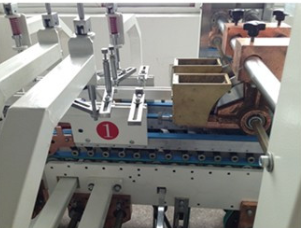

Bottom-lock

3-board tracking structure, upper gluer can make bottom-locked box automatic gluing and forming, can be used for the special-shaped cartons.

The entire bottom-lock part is installed in a reversible bracket, substantially reduce the swap adjustment time of bottom-fold box and the other types of box. Bottom-folding speed is 50-200 pcs per min, stable and reliable.

Lengthened folding to avoid the unevenness while the rapid forming of cartons and make it come to perfection.

Two modes for pressing belt speeding:

Auto: set distance between boxes, pressing belt speed is the same as the machine, belt removes while sensor detect it.

Manual: pressing belt conveys in a fixed speed and machine speed will not put any effect on it.

With counting device to count the finished boxes to match with boxes regulating, easy to count and pack

Equipped with feeding paper inspection device.

Equipped with impacting device to press the paper after accounting and make it easy to pack paper.