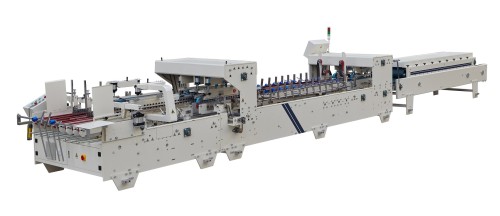

Corrugated Folding Gluing Machine

- Model

- SHH-B2A

Review

Description

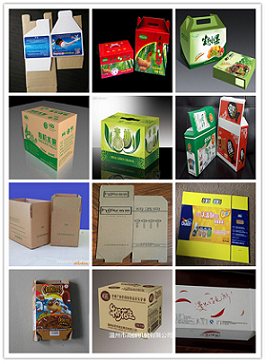

This machine is specially used for paperboard shaping and adhesive processing after cutting horizontally.Its universality is strong and suitable scope is wide, which can fold and paste various straight seaming box.

It is widely used in food, medicine, cosmetics, stationery and other ordinary cartons.perfectly combing the requirements of auto packaging together.

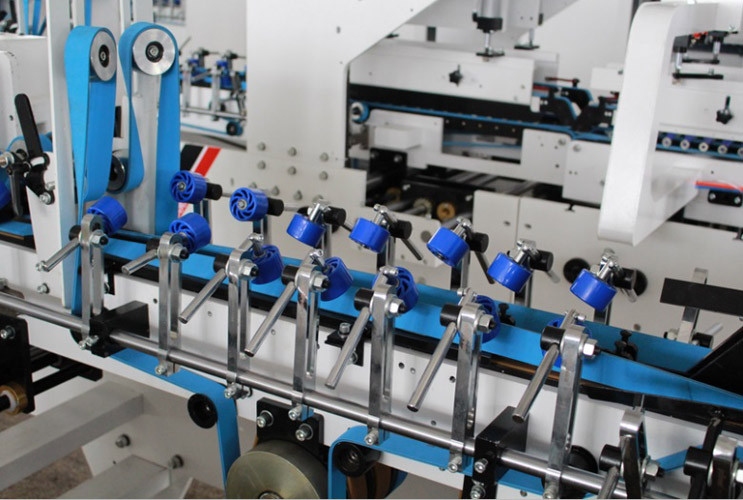

1) Adjustable feeding belts to ensure easy adjustment, stable and smoothly feeding.

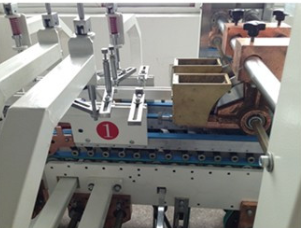

2) Alignment section, which automatically corrects the box after it is ejected from the paper feed section

3) Lengthened folding to avoid the unevenness while the rapid forming of cartons and make it come to perfection.

4) Equipped with impacting device to press the paper after accounting and make it easy to pack paper.

|

Model

|

SHH-1050/1250/1450/1650/1850/2050B2A |

|

Paper Materia |

Cardboard 200-800g A/B/C/E/F-flute |

|

Max. Liner speed |

Max. 220 meter/minute |

|

Feeding way |

Automatically and continuously feeding |

Way of folding | Fold 2 and fold 4 are 180° |

Glue Material | Water-base cold glue |

Electric power | 8KW 380V 50HZ 3P |

Weight | 3400(3800)(4200)(4600)(5000)(5400)KG |

Over dimension | 12000 x1600 (1800)(2000)(2200)(2400)(2600)x 1400mm |

|

Model

|

1050B2A | 1250B2A | 1450B2A | 1650B2A | 1850B2A |

2050B2A |

|

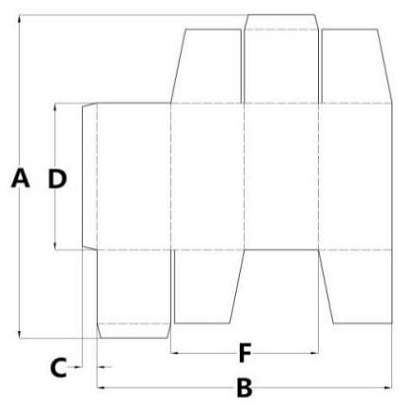

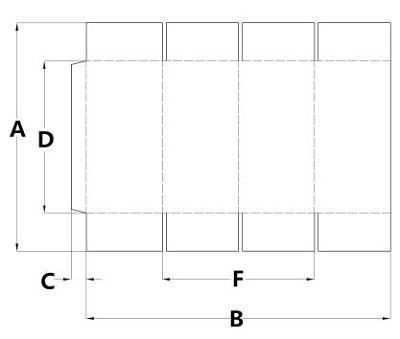

A

|

150-800 | 150-800 | 150-800 | 150-800 | 150-800 |

150-800 |

|

B

|

200-900 | 200-1100 | 200-1300 | 200-1500 | 200-1700 |

200-1900 |

|

C

|

Min:15 | Min:15 | Min:15 | Min:15 | Min:15 |

Min:15 |

|

D

|

Min:120 | Min:120 | Min:120 | Min:120 | Min:120 |

Min:120 |

|

F

|

Min:100 | Min:100 | Min:100 | Min:100 | Min:100 |

Min:100 |

|

Model

|

1050B2A | 1250B2A | 1450B2A | 1650B2A | 1850B2A |

2050B2A |

|

A

|

150-800 | 150-800 | 150-800 | 150-800 | 150-800 |

150-800 |

|

B

|

280-900 | 280-1100 | 280-1300 | 280-1500 | 280-1700 |

280-1900 |

|

C

|

Min:15 | Min:15 | Min:15 | Min:15 | Min:15 |

Min:15 |

|

D

|

Min:120 | Min:120 | Min:120 | Min:120 | Min:120 |

Min:120 |

|

F

|

Min:100 | Min:100 | Min:100 | Min:100 | Min:100 |

Min:100 |

Alignment section, which automatically corrects the box after it is ejected from the paper feed section

Lengthened folding to avoid the unevenness while the rapid forming of cartons and make it come to perfection.

1. 2-board structure

Two modes for pressing belt speeding:

Auto: set distance between boxes, pressing belt speed is the same as the machine, belt removes while sensor detect it.

Manual: pressing belt conveys in a fixed speed and machine speed will not put any effect on it.

2. With counting device to count the finished boxes to match with boxes regulating, easy to count and pack.

2. Equipped with impacting device to press the paper after accounting and make it easy to pack paper.